Table of Contents

This article explores the transformative potential of industrial machinery advancements, highlighting their potential to enhance efficiency, sustainability, and cost-effectiveness in the manufacturing sector.

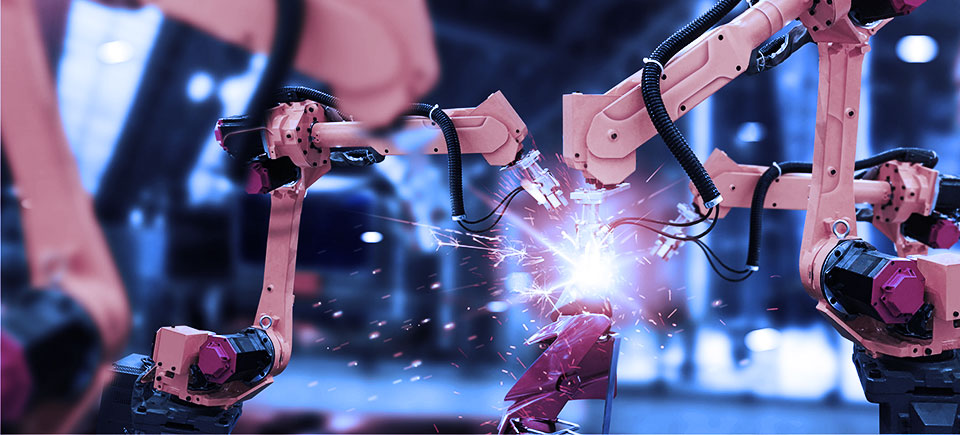

• Revolution in Robotics

Modern robotics is revolutionizing the manufacturing industry by performing complex tasks like quality control and assembly with precision, reducing error rates and production times. Cobots, or collaborative robots, work alongside human operators, boosting productivity without compromising safety. Advanced sensors and machine learning algorithms enable these robots to adapt to their environment, making high-tech manufacturing accessible to a broader range of industries.

• The Impact of IoT

The Internet of Things (IoT) is revolutionizing industrial machinery by connecting physical devices to the internet, enabling real-time data collection and analysis. This allows factories to monitor machines, predict failures, and optimize maintenance schedules. IoT systems track parameters like temperature, vibration, and power consumption, providing actionable insights, improving operational efficiency, reducing downtime, and enhancing supply chain transparency.

• Advancements in AI

Artificial intelligence (AI) is becoming a cornerstone of modern industrial machinery. By integrating AI, machines can make decisions faster and more accurately than humans. Predictive analytics powered by AI can identify potential issues before they become serious problems, offering solutions that preempt costly downtime. Machine learning algorithms analyze extensive datasets to optimize production processes automatically. This means lower waste, higher quality products, and shorter time-to-market. AI is also driving innovation in design processes, enabling the creation of more efficient and effective machinery. The relentless evolution of AI technologies continues to push the boundaries of what industrial machinery can achieve, laying the groundwork for a new era in manufacturing.

• Sustainable Practices

Sustainability is becoming a priority in industrial production. New machinery is designed with energy efficiency and reduced environmental impact in mind. Innovations include machines that use less power, produce less waste, and recycle materials more effectively. Green manufacturing practices are attracting significant attention, guided by regulations and consumer demand for eco-friendly products. Renewable energy sources like solar and wind are being integrated into factory operations. Efficient machinery not only reduces carbon footprints but also lowers operational costs. As the world moves toward sustainable development, industrial machinery is set to play a critical role in reducing the ecological impact of manufacturing activities, making businesses both greener and more competitive.

• Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, is revolutionizing the production landscape. Unlike traditional methods that remove material to create parts, additive manufacturing builds components layer by layer, allowing for intricate and customized designs. This method minimizes waste and accelerates production times. Industries such as aerospace, automotive, and healthcare are leveraging 3D printing for prototyping and producing complex parts that are difficult or impossible to make with conventional techniques. It also supports the development of lightweight components, which can lead to significant fuel savings and performance improvements. As 3D printing technologies continue to advance, they promise to make manufacturing more flexible, efficient, and innovative than ever before.

• The Role of Data Analytics

Data analytics is transforming industrial machinery by offering deeper insights into operational performance. With vast amounts of data collected from sensors and other monitoring tools, advanced analytics can identify patterns and trends that were previously unnoticed. Businesses can now fine-tune machine operations, forecast demand more accurately, and monitor supply chains with unprecedented precision. Predictive maintenance, enabled by robust data analytics, reduces downtime and extends the life of machinery. Furthermore, data-driven decision-making allows for more agile and responsive manufacturing processes. This capability is driving industries toward a future where data is not just a byproduct of operations but an integral part of strategic planning and innovation.

• The Emergence of Edge Computing

Edge computing is emerging as a game-changer in the industrial sector. Unlike traditional cloud computing, which processes data in centralized data centers, edge computing brings data processing closer to the source, enabling faster decision-making. In manufacturing, this means that data from sensors and machines can be analyzed in real-time, on-site. This reduces latency and allows for immediate responses to system anomalies or production inefficiencies. Edge computing also enhances cybersecurity by limiting the amount of data sent over the internet, reducing vulnerability to cyber-attacks. As machinery becomes more interconnected and intelligent, the adoption of edge computing will be crucial for maintaining seamless and secure operations.

• Customization and Flexibility

The future of industrial machinery is characterized by customization and flexibility. Modern manufacturing demands more adaptable equipment that can quickly switch between different tasks and product types. Advanced software systems enable machinery to be reprogrammed rapidly, paving the way for customizable production lines. This flexibility is essential for meeting the ever-changing market demands and consumer preferences. Companies can now produce small batches tailored to specific customer needs without sacrificing efficiency or cost-effectiveness. Flexible machinery supports innovative business models like mass customization and just-in-time manufacturing, allowing businesses to stay competitive in a fast-paced market environment. This shift towards adaptable production setups is redefining the boundaries of what’s possible in industrial manufacturing.

• Conclusion

The future of industrial machinery is bright and filled with promise. Advancements in robotics, IoT, AI, sustainable practices, additive manufacturing, data analytics, edge computing, and customization are setting the stage for a new era of industrial production. These technologies are not just improving efficiency and reducing costs; they’re also enabling safer, more sustainable, and more responsive manufacturing processes. As these innovations continue to evolve and integrate, businesses that embrace them early will be well-positioned to lead in a rapidly changing industrial landscape. The transformation of production through advanced industrial machinery is a testament to human ingenuity and the relentless pursuit of progress. The synergy of these technological advancements will undoubtedly shape the smart factories of the future, making production more intelligent, efficient, and sustainable.